Designed for online calculation of the ovulation period, favorable and safe days...

Dear gardeners! The company "Volya" is pleased to present you a novelty of 2015 - arched greenhouse with a sliding roof "Present".

Unlike other greenhouses from a pipe, in this sheet cellular polycarbonate they are not screwed to the frame, but are inserted into special plastic profiles along which they move up and down. Thus, the roof can be moved down on both sides independently of each other, and also fixed in the ajar position.

Thanks to the sliding roof, you get uniform ventilation along the entire length of the Present greenhouse, which is very important on hot summer days. In winter, the lack of a roof saves you from having to come to your dacha to clean the greenhouse from snow, which, moreover, getting inside, protects the top fertile soil layer from freezing.

The frame of the greenhouse is made of a profile pipe 33x33 mm. The absence of snow load made it possible not to install arc amplifiers. This had a positive effect on the final price of the greenhouse, and also simplified its assembly.

The dimensions of the greenhouse with a sliding roof remained classic for arched models: width - 3 meters, height - 2.2 m, length can be any, most importantly - a multiple of two meters.

Greenhouse "Present" is reliably protected from rust! The profile pipe used in the greenhouse was made directly at the Volya plant and differs from the others in a thicker layer of zinc and the absence of a weld. It is obtained by bending and joining galvanized sheet steel into a lock.

| Greenhouse "Present" - width 3 m / Length: | 4.16 m | 6.23 m | 8.3 m | 10.36 m |

| Frame price without polycarbonate | 29200 r | 37800 r | 46400 r | 55000 r |

| Price with thin polycarbonate STANDARD 4mm | 37400 r | 47900 r | 58400 r | 68400 r |

| Price with durable polycarbonate PREMIUM 4mm UV | 40900 r 39900 R |

53500 r 52000 R |

66200 r 64200 R |

78800 r 76300 R |

| Services and extras equipment | 4 meters | 6 meters | 8 meters | 10 meters |

| Service "Assembly and installation in the ground" ( |

The Nurse-Umnitsa greenhouse produced by the Metal-Service plant is considered the Siberian brand No. 1. Since it was modified with an opening roof, Clever has gained even more followers and customers. So how is it different? characteristics of the greenhouse detailed instructions assembly and reviews of farmers - on our website. Additional information - in a visual video.

At the Metal-Service plant located in Novosibirsk, several types of greenhouses are produced: Crab, Bogatyrskaya, Nurse Room and a large industrial one.

As the producers explain, since 2008 they have been trying to create another version of the greenhouse suitable for Siberian summer residents. The new model had to withstand harsh winters and serve for a long time. In 2010, after the successful implementation of the idea, the tested greenhouse was put into production. Thanks to rave reviews, she got her affectionate name "Nurse-Clever". The design was awarded at various exhibitions, successfully tested by scientists at the Siberian Institute of Plant Growing and Breeding.

But the developers didn't stop there. They managed to fulfill another request of farmers - the maximum possible ventilation. In 2015, the "Nurse" with an opening top was presented to the public. As Revaz Zarkua, the director of the Metall-Service plant, said: “A distinctive feature of this greenhouse from all those produced earlier is a fully opening roof.”

This type of greenhouse, like other brands of the same plant, is characterized by increased frame strength. Almost all greenhouses on various sites are called durable. But if evaluated on a 10-point scale, the "Nurse" is strong for ten, otherwise the model would not have survived the Siberian snow.

"Nurse-Clever" is made of a steel pipe with a square section of 20 by 20 mm. with polymer coating. The arcs of the arched structure are located every meter, the thickness of the walls is 1.5 mm, the width of the greenhouse is 3 m. Length 4-10 m., and it can be increased in stages.

Some versions of the "Nurse" are available with a wall thickness of 1.2 mm. Therefore, in topics discussing the greenhouse, there are doubts about durability. However, the owners of the novelty immediately respond that such a frame seems thin, but in fact it is quite reliable.

Attention! If the purchased greenhouse has a flaw, for example, it will be crushed by snow with the roof closed, the manufacturer promises to completely replace it.

Greenhouse features:

It seems that two doors and two vents are enough for ventilation. In addition, another additional transom with automatic opening has been developed, which can be completed with a greenhouse. Why then the opening top? Consider all the benefits of new items:

As stated on the manufacturer's website, the Umnitsa greenhouse with an opening roof is sold in different configurations. A minimum kit is offered worth up to 20,000 tr. or a kit with additional elements from 20,000 to 30,000 tr. Assembly is charged separately.

When choosing a location for the Nurse, you need to consider a few simple rules:

![]()

Judging by the reviews of the owners, the installation of the greenhouse is not difficult, you just need to do it in the right sequence. To begin with, decide whether to put the greenhouse on the foundation or on a rectangular support.

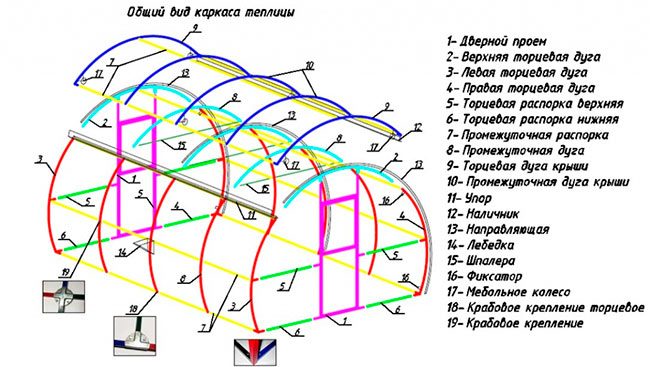

Greenhouse frame diagram

Advice. Bolts are advised to be placed from the bottom of the metal. Because the lower part will be installed on the foundation or support.

As a support, you can use everything that is at hand. For example, a bar fastened with corners and self-tapping screws. Or bricks laid out around the perimeter of the greenhouse. Then you can start assembling:

Attention! The middle pipe should be fastened exactly in the middle between the left and right edges. A small error can lead to malfunctions of the mechanism.

Greenhouse Nurse-clever on the site

Winter is one of the most important problems of almost every ordinary owner. After all, it is during this season of the year that the building, which is intended for growing various crops, is going through "not the best of times."

So, an ice crust is gradually accumulating on the roof of the structure, adversely affecting the state of the greenhouse. There are two ways out of this situation - every year to assemble and disassemble the roof of the greenhouse, or to make a special co removable roof .

It should be noted that reliable protection against a break under a load of ice and snow is not the only advantage that this type of greenhouse has.

Want to know more? Subscribe to our VK public, there is all the most delicious from the editors and interestingness from readers:

In contact with

One of the most important advantages of a removable top greenhouse is its relatively low cost, which is only about 5% higher than the cost of simpler designs.

Also to the advantages of a greenhouse with a removable roof Other technical features include:

As a result, a longer service life is guaranteed, because under heavy layers, especially wet snow, even the most “high-quality” frame can collapse;

It is an original alternative to conventional vents. Such ventilation takes place evenly and without the appearance of drafts, which adversely affect the development of all crops;

First of all, you need to choose personal plot place to be well lit for a long time, as a result of which a large number of sunlight. It is desirable that the surface of the site be flat and not even under a subtle slope.

When choosing a place for a greenhouse, you should also not forget that it shadows from tall trees should not fall and nearby buildings, so the area should be as open as possible.

And the most important criterion for choosing a site is that nothing should prevent the quick removal and return of the roof back.

Typically, such greenhouses are not used in. This is due to the peculiarities of their design.

So, in most cases, the roof is removed specifically so that snow does not accumulate on its surface, and an ice crust does not form. In addition, this allows create uniform pressure on the walls of the building on both sides, which significantly reduces the risk of its destruction. However, in warmer regions, such greenhouses are sometimes operated during the cold season.

In addition, you should decide in advance what type of greenhouse with a sliding top will be - stationary, folding or.

The most optimal option is a stationary greenhouse. However, folding and portable greenhouses differ in one important feature, which is that, if necessary, the structure can be disassembled and hidden in any convenient place or changed its location without putting too much effort.

However, greenhouses of a stationary type have (usually a tape shooting gallery), which, in fact, causes them to be more high resistance to sufficiently high loads as well as weather conditions.

The next stage of preparatory work is to determine the parameters of the future greenhouse. Its dimensions should correspond to the type of plants that will be grown in it.

The most optimal parameters are considered to be a height of 2 meters and a width of 10 meters. Such designs are characterized by versatility and are perfect for growing cucumbers or undersized bushes, as well as for seedlings of fruit trees.

Then you need to compose. In this diagram, all the details of the structure must be marked, starting with the door and ending with small ventilation holes.

To date, distinguish several types of greenhouse designs equipped with a removable roof:

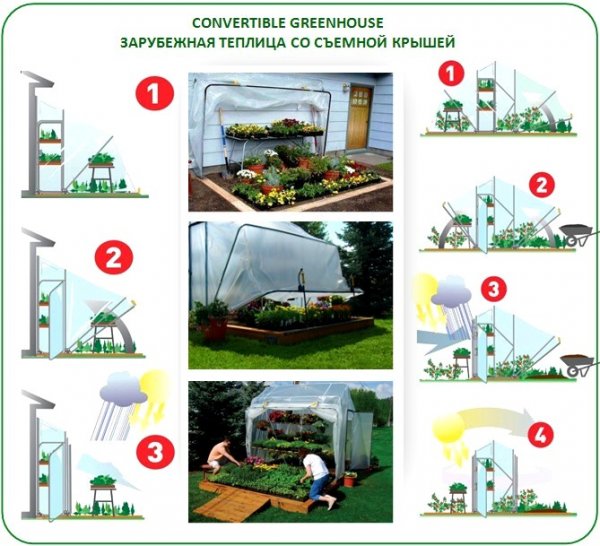

Recently, the so-called convertible greenhouses. Their widespread use is due to the rather simple technology of installation and use.

This greenhouse with opening top is an option, equipped with special vents. In this case, the roof does not need to be removed - it only moves from the sides.

In the warm season, a similar mechanism is used as ordinary vents, and in the cold season it ensures that snow gets inside onto the soil. So, after the completion of the harvest, you just need to move part of the roof of the greenhouse.

It should be noted that such designs provide for the presence of two compartments, in each of which you can create completely different conditions for growing vegetables and other plants.

In addition, you can give preference to the second design option, in which the meter sheet must be shifted down.

To build a greenhouse with a sliding top, you must perform the following steps:

Many owners of this type of greenhouse claim that this ideal for successful crop production. However, such structures also have a drawback - poor tightness, which sometimes does not save plants from heavy rain showers.

Watch the video: a country greenhouse with a roof removed for the winter and other types of removable roofs for greenhouses

In contact with

See inaccuracies, incomplete or incorrect information? Do you know how to make an article better?

Would you like to suggest photos for publication on a topic?

Please help us make the site better! Leave a message and your contacts in the comments - we will contact you and together we will make the publication better!

| 5319 | 0 |

Recently, it has been very popular. For any greenhouse, the roof is the main structural element. It is she who has to cope with wind and snow loads.

They are strong enough, transparent, with their help the internal space is well ventilated.

Also, the roof of the greenhouse can open, move, move apart in different directions. Today it is easy to find a detailed guide on how to assemble a greenhouse with an opening roof with your own hands.

The most widespread are the following varieties:

There are versions in which polycarbonate or glass roofs have an unusual shape. There is no functional load in them and a purely decorative function prevails.

Sliding roof greenhouses are especially popular. It has an advanced ventilation system, thanks to which it is possible to grow plants on almost open field. Sliding greenhouses are equipped with manual and automatic mechanisms that are responsible for quickly isolating the internal space from the negative manifestations of the external environment.

The most widespread are reliable and ergonomic mechanisms, called:

Sliding roof structures can be folded onto winter period. So you can minimize the dimensions of the surface, which have to withstand snow loads. The assembled device opens in minutes.

Manufacturers offer a wide range of special mechanisms that can automatically open / close the windows of various structures. Devices operate according to this principle: a special liquid placed in a cylinder is limited on both sides by pistons. When the temperature exceeds the threshold values, the piston presses on the rod. Greenhouse windows begin to open slightly.

As the outside temperature increases, the gap becomes larger. If the temperature drops, then the volume of the liquid decreases, and the pistons (under the influence of an internal spring) return to their original state.

By installing a similar mechanism, any gardener can improve the design of a standard metal profile greenhouse by adding folding windows or a sliding roof. There is a double folding greenhouse.

Installation is carried out as follows:

There are modifications in which the roof of the greenhouse swings open completely. Here the interior space is cooled most efficiently. But this method should be used carefully, as plants can catch a cold.

The most profitable option is to use ready-made sets of automatic ventilation systems in greenhouses. Devices can be mounted on any structures that are equipped with hinged hatches or a sliding roof.

Have you ever experienced joint pain? And you know firsthand what it is:

Please answer the question: are you satisfied with this? Can such pain be endured? How much money have you already "leaked" for ineffective treatment? Time to end this! Do you agree? Today we are publishing an exclusive interview with Professor Dikul, in which the doctor revealed the secrets of getting rid of joint pain, treating arthritis and arthrosis.

Did you like the material? Be sure to save it to your social networks, or just print it.

The dream of every summer resident is to have their own greenhouse to extend the summer on cold autumn days. Those who have financial security can purchase a greenhouse and assemble it on the spot. The craftsmen themselves will make the frame and cover it with the selected material. Recently, proposals have been gaining momentum to assemble a greenhouse from ready-made parts, with different configurations - from a greenhouse, "matryoshka", "asterisks" with a removable roof, to a "convertible" - a greenhouse with an opening roof, made of different materials.

Preference in proposals is given to a metal frame protected from environmental influences and polycarbonate, covering material for roofs and walls, which has unique properties: high light transmission, durability in use, low specific gravity, which makes it possible to assemble and disassemble, mount with attraction to the work of a small number of assistants and other qualities. Transformer greenhouses are very convenient and everyone can choose the option he likes.

The main element of the greenhouse is the roof. It provides lighting, protection from unwanted precipitation, including rain with "chemicals", snow, hail, etc. A summer resident's dream is a roof that does not let in lethal doses of ultraviolet radiation, from which it is easy to remove accumulated snow and carry out ventilation without drafts. All these qualities are possessed by transformer greenhouses.

Greenhouse with removable roof

Before buying such a collapsible greenhouse, you need to read the instructions from the manufacturer to make sure that you can assemble the greenhouse yourself or invite specialists.

After studying the instructions, make sure in practice that all elements and fasteners of the structure are effortlessly mounted and joined, especially a removable or hinged roof, doors and vents, and wall parts easily slide in slide grooves.

Greenhouse Matryoshka, fixing sections

Transformer-greenhouse "Dachnaya Zvezdochka" is an unheated version of greenhouses for warm regions and areas with limited use during the year. The frame of the greenhouse is represented by a profile with an anti-corrosion coating. Panels, wall and roof, polycarbonate, material thickness is 4 mm. The panels are inserted into the grooves, easily removed selectively one by one or all if necessary. The roof of the building is double pitched. The lifting mechanism provides good ventilation, and for the winter the cover is completely removed, which allows the greenhouse soil to be protected by a layer of snow from deep freezing and no snow load is created on the roof of the greenhouse structure.

"Country Asterisk" with the roof removed

The greenhouse is suitable for a small family in size Standard dimensions: length 2.17 m, width 2.52 m and height 2.23 m. Due to the sliding panels, the greenhouse area can be increased with inserts of 2.12 m. There are 2 doors and 4 vents in the greenhouse located at the ends. The greenhouse is installed on the ground or foundation, it can be made of beams or tape stone. The design allows the cultivation of tall crops, with sufficient light and heat.

The transforming greenhouse "Matryoshka" can be used in the hot south and in regions with fairly snowy winters. To install a greenhouse, a flat area with uniform lighting is required. Installed without foundation. The package includes special stakes for fixing the frame of the greenhouse. The frame of the transforming greenhouse "Matryoshka" consists of steel pipes galvanized from the inside and outside in the form of arcs. All parts of the greenhouse are easily disassembled for the winter. The greenhouse is sliding. The roof is completely removable. Appearance hemisphere roofs, which are shifted to the ends for the winter if the greenhouse cannot be disassembled.

Greenhouse "Matryoshka"

During operation, the panels are shifted and fixed with brackets. Covering of end panels and roof made of honeycomb polycarbonate. Fixing the cover does not require drilling of frame arcs. They are fixed with special brackets. In a collapsible form of a greenhouse, the soil receives all the necessary nutrients from the environment.

Standard length and width 3.0 m, height 2.15 m. The greenhouse is able to withstand temperatures ranging from -40 to +60°C.

Greenhouse "Matryoshka", assembly for the winter

The transforming greenhouse "Cabriolet" with an opening roof is designed specifically for regions with extreme winters. To increase strength and stability in case of weather disasters, the greenhouse frame (arch and base) is all-welded from a steel profile pipe. She is very compact. The standard dimensions of the greenhouse are the width and height of 1.3 and 1.2 m, respectively. The length is arbitrary from 1.6 to 5.0 m in increments of 1.7 m. The dimensions can be large - width 2.8 and height 2.2 m. The step of the arc is 1 m.

Polycarbonate sheets 4 mm thick, parameters are 6.0x2.1 m. There are 2 doors with vents. A stable greenhouse that does not require a foundation for installation. If desired, it can be installed on a foundation of timber, concrete, bricks. Distinctive feature - compact dimensions and ease of operation. Quick installation and dismantling of the roof and the entire greenhouse if necessary. In anticipation of snow blizzards, the roof is shifted like old convertibles or removed completely.

Greenhouse “Cabriolet”

In addition to transforming greenhouses Cabriolet, summer residents are offered another option for protected ground, the Cabriolet greenhouse. Outwardly, it resembles a greenhouse of the same name, but more compact and is intended for growing low crops of one or two species (cucumbers or tomatoes with peppers, a set of greens, salads).

As a rule, the greenhouse has an arched shape, along the length it can be divided into several sections. A separate crop is grown in each section.

Corrosion resistant steel tube frame. Sections can be opened by simply lifting the handle from either side, which is very convenient. The greenhouse is convenient because it does not take up much space and does not require special care.

Greenhouse “Cabriolet”

The proposed models of modern greenhouses are very easy to use, affordable. Does not require engineering knowledge during installation. They have a long service life. Sometimes there are complaints that removable roofs will not withstand the load and may collapse. The polycarbonate roof can withstand a load of more than 50 kg. Therefore, if it is necessary to prepare the soil early for sowing, the roof can not be removed from greenhouses and transformer mini-greenhouses. Removable roofs are also convenient because when it is removed, the soil is saturated with moisture and necessary nutrients during the winter, the soil does not freeze through and will be ready for seasonal work. The ends (walls) of the greenhouse will be evenly (on both sides) covered with snow. The product itself will not suffer, it will remain intact.